Today’s adventures in furniture restoration delve into the enigmatic world of the bureau. This piece, a captivating mix of quality craftsmanship and curious construction choices, presents a fascinating puzzle.

Mantid Munchies and Thailand’s Marbled Marvels

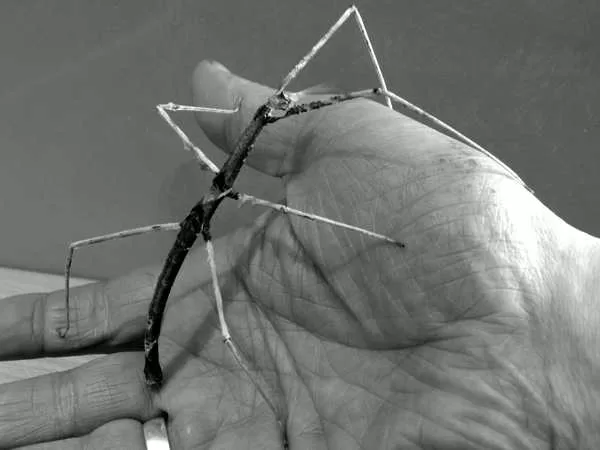

Before we dive into the bureau’s mysteries, let’s acknowledge the new arrivals – a culture of wingless fruit flies (a delightful snack for the mantids) and a colony of Thailand Marbled Stick Insects (Parapachymorph zomproi). These enchanting creatures, known for their beautiful mottled patterns and long, thorny limbs, will be thriving on a diet of bramble leaves. Interestingly, this species boasts a rapid egg-hatching period of just 2-8 weeks, making them fascinating additions to the insect world.

The Art of Furniture Appraisal: A Beginner’s Guide

Now, back to the bureau. Appraising furniture often involves a meticulous process, and the drawers are a great starting point. Ideally, all drawers should match in size and construction. Examining a single drawer in detail reveals valuable clues. The wood inside is likely oak or pine, different from the exterior wood. Look for dovetail joints, a sign of quality craftsmanship, which this bureau possesses.

Flipping the drawer reveals even more details. Look for wear or worm damage on the bottom. Well-made pieces often have drawers secured with small brass screws, another positive sign for this bureau. The absence of asymmetrical wear indicates smooth drawer operation, further suggesting good construction.

The Bureau’s Paradoxical Design

However, the drawer front presents a curious anomaly. While the dovetail joints and brass screws point to quality, the use of plywood with a veneer facing deviates from typical solid wood construction in high-end pieces. This hints at a more economical approach.

The plot thickens with the presence of cross-banding on the veneer. This technique, normally indicative of quality due to its increased complexity, seems at odds with the use of plywood.

Hidden Costs and Smart Construction

It’s common for furniture carcasses (the main body) to be crafted from less expensive wood, as these parts are typically unseen. However, the use of plywood as a base for drawer veneer is an uncommon choice.

Environmental Impact and Decoding the Cracks

The veneer crack on the right drawer is likely due to uneven drying. While direct sunlight could be a culprit, the consistent color suggests another cause – central heating. Uneven heat exposure can dry out wood, causing cracks. To remedy this, a generous application of almond oil was applied, followed by a beeswax, turpentine, and linseed oil mixture for further enrichment.

A Handle on the Situation and Finishing Touches

The missing drawer handle found a new home on the drawer front, highlighting another interesting detail. The nuts securing the handles on both drawers and the door have metal caps, a mark of quality furniture. Typically, these nuts would be left exposed.

The restoration process concluded with a thorough cleaning and waxing of the entire bureau. Finally, the missing keyhole escutcheons were replaced using a hide mallet to avoid surface marks.

The Bureau’s Legacy: A Work in Progress

The bureau, with its intriguing blend of high-quality elements and cost-saving measures, remains an ongoing puzzle. As the restoration progresses, perhaps more clues will emerge, revealing the story behind this unique piece.